Brown corundum

Brown corundum (CAS No. 1302-74-5) is made of bauxite and coke (anthracite) as the main raw materials. It is smelted at high temperature in an electric arc furnace. The abrasive tools made of it are suitable for grinding metals with high tensile strength, such as various general steels , Malleable cast iron, hard bronze, etc.

product Introduction

Brown corundum (CAS No. 1302-74-5) is made of bauxite and coke (anthracite) as the main raw materials. It is smelted at high temperature in an electric arc furnace. The abrasive tools made of it are suitable for grinding metals with high tensile strength, such as various general steels , Malleable cast iron, hard bronze, etc. It can also be used to manufacture high-grade refractory materials. Brown corundum has the characteristics of high purity, good crystallization, strong fluidity, low linear expansion coefficient and corrosion resistance.

Product Features

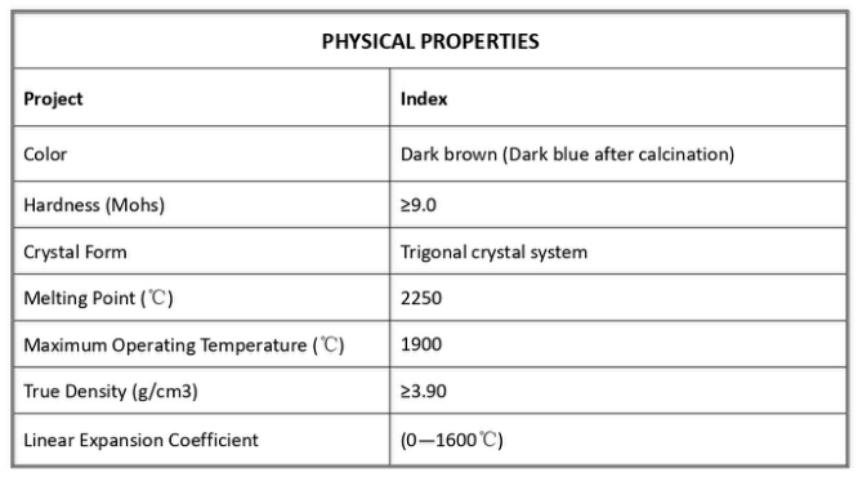

Color: dark brown (dark blue after calcination)

Crystal shape: Trigonal crystal system

Hardness (Mohs): ≥9.0

Melting point (℃): 2250

Maximum operating temperature (℃): 1900

Application Field

- Mainly used in refractory materials, grinding wheels, sandblasting, hydraulic cutting, etc.